Metal Channel Strip Brushes

Flex-Guard’s metal channel strip brushes are simple to manufacture, ideally suited to highly automated, high volume production and, after basic manufacture, can be easily coiled or formed into special shapes and configurations and combined into special assemblies.

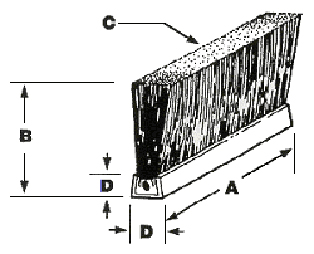

Flex-Guard® manufactures metal channel strip brushes by laying filaments (natural, synthetic or wire) over a continuous metal channel while it is being formed into a “U” shape. A binding wire is forced down into the partially formed channel, forcing the bristle material down to the bottom of the newly formed channel. The bristle material aligns vertically as the strip is closed together. Brushes are then trimmed to the required height and cut to length automatically. Pieces as short as 3/8″ are possible in the smaller strip sizes and lengths up to 12 feet are easily manufactured – contact us if longer lengths are needed.

Channel Materials

Different manufacturers may use the same Size, Letter or Number for a metal channel strip brush. There are often significant differences in the actual dimensions after forming. Considering this, if the metal channel strip brush is to be inserted into an extrusion, holder, bracket assembly or mating part; it should be submitted by the customer and retained by Flex-Guard to be used as an additional gauge to ensure proper fit.

Flex-Guard‘s unique “h” back metal channel strip brush combines brush and mounting flange into one unit. For the OEM designer, maintenance or process engineer, “h” back strip brushes eliminate parts, facilitate assembly and reduce cost and installation time. A wide range of special options and additional sizes are available to the OEM user. In addition, five standard size “h” back brushes with a variety of bristle materials are available from stock.

Optional Channel Shapes

Many styles and shapes are possible in special metal channel strip brushes. Tooling for forming tools would be required. Some of the special shapes we have produced are:

If you have a specific requirement for a special metal channel strip brush shape, please request a quotation.

FLEX-GUARD flexible containment seals solve in-plant problems with air, dust, sound, light, chips, spray and pest control. Stocked in 12′ lengths…in 16 extrusions or holder shapes and up to 10 separate brush heights per size. We offer the design and production engineer nearly one-hundred variations of brush seal products…from stock, in twelve bristle textures and materials.

Configurations

Metal channel strip brushes can be manufactured in a wide range of standard and special configurations. The metal holding channels (of steel, stainless or brass) and metal or plastic binding wires offer malleability for forming and coiling yet provide consistent dimensional stability and repeatability with structural integrity. Virtually any type of filament can be inserted into the metal channel as well as solid materials such as felt, plastic and rubber; alone, or combined with the bristle material. The advantage of Flex-Guard’s metal channel strip brush construction is that, along with the wide range of design possibilities, metal channel strip brushes require minimum labor and low tooling costs for high output production on a highly repeatable basis.

A METAL CHANNEL STRIP BRUSH OFFERS MAXIMUM DESIGN FLEXIBILITY:

– Widths from .100″ to .465″

– Formed Shapes

– High Volume Production

– Close Tolerances

– Coils, Internal and External

– Ideal for Assemblies

![]() Download Metal Channel Strip Brushes – PDF

Download Metal Channel Strip Brushes – PDF

QUIET ENVIRONMENT • NON-ABRASIVE SURFACE • SMOOTH OPERATION

Metal Channel Strip Brushes Design Specification

Flex-Guard has a wide variety of different size Metal Channel Strip Brushes. Let us help you design the right Metal Channel Strip Brush for your application. For more information on Flex-guard Metal Channel Strip Brushes Design Specification, please complete the form below and press Send. All measurements are in inches.

Metal Channel Strip Brushes Quote Form:

Note: If brush is to fit a holder, please furnish one to us in order to ensure a proper fit.

Note: Please indicate any critical tolerances