Metal Channel Brushes

Flex-Guard’s metal channel brushes consist of natural, synthetic filaments, or made of wire pressed together to form many different shapes and configurations pending their application environment. These brushes include metal channel strip brushes, disc seals, ring seals, and a few different types cylindrical coil brushes, such as internal and external cylindrical coil brushes or fixed on a shaft. The metal channel width and the length of brush bristles can be trimmed to fit any job solution in the industrial manufacturing environment. These styles and types of brush enclosure is for highly automated, high volume production, and manufactured to prevent noise, chips, light, dust, vibration, air coolant mist and temperature.

Metal Channel Brush Product Solutions:

- Cart Rail Brushes

- Chip Containment

- Hood Seals

- Paint Booth and Washer Closeouts

- CNC Router Spindle Head shrouds

- Sandblasters Hood Seals

- Conveyor Cleaning Brushes

- Conveyor Track Closeouts

- Machine Guards Brush Mounting

- Generator Seals

- Lead Screw Seals

- Pipe Seals

- Rotating Shaft Seals

- Shaft Seals

- Sliding Tube Seals

- Laser Sight Seal

- Lever Seals

- Sight Seals

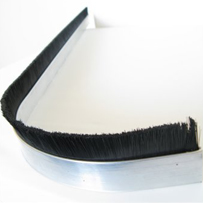

Metal Channel Strip Brushes

Flex-guard® manufactures metal channel strip brushes by laying filaments (natural, synthetic or wire) over a continuous metal channel while it is being formed into a “U” shape. A binding wire is forced down into the partially formed channel, forcing the bristle material down to the bottom of the newly formed channel.

Disc Seals – Single Seal

Brush ring seals and brush disc seals are used as a method of chip containment, dust containment, and noise containment between two moving parts. The moving parts can be rotating shafts, oscillating tubes, sliding pipes, individual or groups of wires, and chain pulls of dock levelers, to name just a few ring seals and disc seals applications.

Ring Seals – Multiple Seals

Flex-guard® manufactures straight strip brush contoured into a circle consisting of a metal outer ring with internal brush bristles. Brush ring seals and brush disc seals are used as a method of chip containment, dust containment, noise containment plus more between two moving parts.

Cup Brush Seals

Cup brush seals are basically a strip brush looped laterally to form a circle shape. These are made to suit a particular task. They are most often used as a seal around a cylindrical rotating piece, like a drill bit or grinding device. The cup brush shields the operator from chips or dust flying into its surrounding area.

External Cylindrical Coil Brushes

An external cylindrical coil brush is a long strip brush wound in a helical fashion to create a cylinder. These can be nearly any diameter and length, depending on the job they need to perform. Further, some of these cylindrical coil brushes can be closely wound so that they appear as solid cylinders.

Internal Cylindrical Coil Brushes

An internal cylindrical coil brush is a long strip brush wound in a helical fashion to create a cylinder. These can be nearly any diameter and length, depending on the job they need to perform. Further, some of these internal cylindrical coil brushes or shaft cleaning brushes can be closely wound so that they appear as solid cylinders.

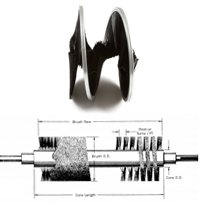

Cylindrical Coil Brush on Shaft

Cylindrical coil brushes on shaft are made from spiral wound cylindrical brushes. They can be very small to very large. These brushes can have left or right hand lead. The brushes can be mounted permanently to a shaft with the use of clips, J-bolts or welded.

Metal Channel Brush Data Sheets:

![]() Download Metal Channel Strip Brushes PDF

Download Metal Channel Strip Brushes PDF

![]() Download Disc Seals – Single Seal PDF

Download Disc Seals – Single Seal PDF

![]() Download Ring Seals – Multiple Seals PDF

Download Ring Seals – Multiple Seals PDF

![]() Download External Cylindrical Coil Brushes PDF

Download External Cylindrical Coil Brushes PDF

![]() Download Internal Cylindrical Coil Brushes PDF

Download Internal Cylindrical Coil Brushes PDF

![]() Download Cylindrical Coil Brush on Shaft PDF

Download Cylindrical Coil Brush on Shaft PDF