In the ever-evolving world of industrial and commercial businesses, finding the right sealing solutions is essential. The difference between a reliable and efficient operation and one plagued by issues often comes down to the choice of seals. This is where FLEX-GUARD® shines, with its extensive range of brush seals designed to cater to a multitude of applications. In this comprehensive guide, we’ll delve deep into the world of FLEX-GUARD®’s brush seals, including custom brushes, brush tables, flexible strip brushes, and industrial brushes, to help you make informed decisions for your unique requirements.

FLEX-GUARD®: A Brief Introduction

Before we embark on this journey through the world of brush seals, let’s start by introducing the stalwart of the industry – FLEX-GUARD®. With a reputation for excellence and innovation, FLEX-GUARD® has been manufacturing and designing brush seals for industrial and commercial businesses for many years. Their commitment to quality and customization has made them a preferred choice for sealing solutions.

The Versatility of Custom Brushes

Custom brushes, the heart and soul of FLEX-GUARD®’s product range, are designed with one principle in mind – tailored excellence. These brush seals are all about adaptability and precision. Whether you need them for sealing machinery, garage doors, or unique industrial applications, FLEX-GUARD® ensures your custom brushes are designed to meet your exact specifications.

Key Features of Custom Brushes:

• Tailored to Your Needs: FLEX-GUARD® custom brushes can be tailored to meet your specific requirements. You have the freedom to choose the bristle material, density, and holder design to ensure a perfect fit.

• Versatility: These custom brushes find applications in a wide range of settings, making them a versatile choice for various industries.

Flexibility with Flexible Strip Brushes

The name says it all – flexible strip brushes are all about adaptability. FLEX-GUARD®’s flexible strip brushes are known for their versatility and durability. They can be effectively used for sealing applications in various settings, including door systems, conveyor belts, and more. These brushes are designed to prevent the ingress of contaminants and provide efficient insulation.

Key Features of Flexible Strip Brushes:

• Adaptability: Flexible strip brushes can conform to various shapes and surfaces, making them a versatile choice for different applications.

• Contaminant Prevention: They effectively prevent the ingress of dust, debris, and contaminants, ensuring a clean and protected environment.

Durability with Industrial Brushes

In the rugged world of industrial settings, durability is non-negotiable. FLEX-GUARD® understands this well and offers a range of industrial brushes designed to withstand even the harshest conditions. These brushes ensure the smooth operation of your machinery and equipment, making them an ideal choice for manufacturing and processing facilities.

Key Features of Industrial Brushes:

• Rugged Construction: Industrial brushes are built to withstand challenging conditions, ensuring long-term performance.

• Efficiency: They play a crucial role in the smooth operation of machinery, reducing the risk of downtime.

The “Top 4 Brush Solutions”

As you explore FLEX-GUARD®’s catalog, you’ll come across the “Top 4 Brush Solutions,” each designed to address specific sealing needs. Let’s take a closer look at these top solutions:

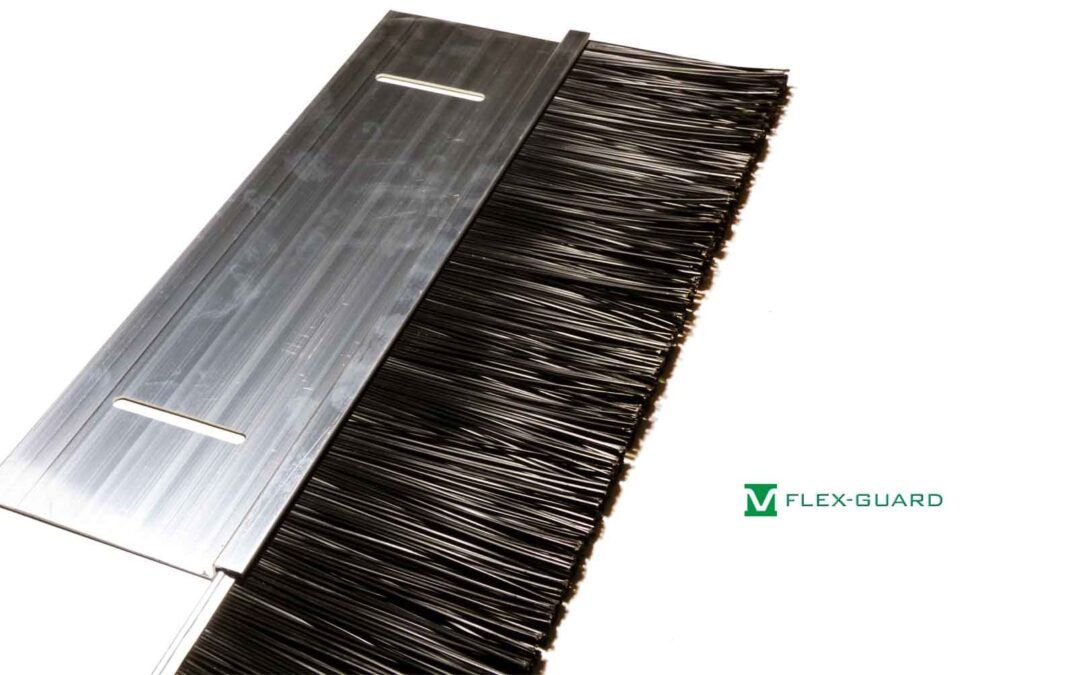

1. Metal Channel Brushes

Metal channel brushes are a versatile solution, ideal for applications where robust sealing is required. These brushes are known for their durability and can be used in various industrial and commercial settings.

Applications:

• Conveyor Systems

• Industrial Equipment

• Manufacturing Facilities

Key Features:

• Sturdy metal construction for long-lasting performance.

• Effective sealing for machinery and equipment protection.

• Versatile applications in industrial settings.

2. Flexible Strip Brushes

Flexible strip brushes, as mentioned earlier, offer adaptability and efficient sealing. They are commonly used for creating airtight seals, noise reduction, and providing insulation in diverse applications.

Applications:

• Doors and Windows

• Conveyor Systems

• Cleanroom Environments

Key Features:

• Conforms to various surfaces for effective sealing.

• Reduces noise pollution and provides insulation.

• Prevents the ingress of contaminants.

3. Conveyor Track Brushes

Conveyor track brushes are a specialized solution designed for conveyor systems. They play a crucial role in preventing debris and contaminants from affecting the conveyor’s operation.

Applications:

• Conveyor Systems

• Material Handling

Key Features:

• Effective at preventing contamination in conveyor systems.

• Ensures the smooth operation of conveyors.

• Reduces maintenance and downtime.

FLEX-GUARD® has established itself as a leading provider of brush seal solutions for industrial and commercial businesses. Their range of custom brushes, brush tables, flexible strip brushes, and industrial brushes offers versatile and tailored solutions for a wide array of applications. When it comes to sealing solutions, FLEX-GUARD® stands out for its commitment to quality, customization, and adaptability.

FLEX-GUARD®’s brush seals are designed to meet the highest standards of quality and performance. Whether you need a custom solution or one of their top 4 brush solutions, you can trust FLEX-GUARD® to deliver reliable and efficient sealing for your unique needs.