Button Brush Tables – Bed Brushes

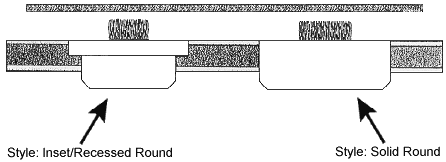

Button brushes and shaped brushes provide effective solutions for Computer Numerical Control (CNC) machine tools. They offer a friction-less solution for sheet metal processing while moving along the brush tables. Their application provides a perfect solution for CNC table brushes and turret punch presses.

In summary, button brushes are the perfect solution for mechanical equipment, electrical equipment, punch presses, and table feeds.

When using the button brush, materials get transported without the risk of damage through friction or material on material interaction. The material transportation is in a stable and controlled manner. The brushes can both serve the purpose as a surface or directional guides. The button brush provides a significant noise and shock reduction, avoiding any risk of damage to the material.

Brush tables with button brushes cut noise levels, stabilize conveyor traffic, and closeout paint booth tracks. When your parts need to move along a machine bed for further fabricating, you don’t want them scratched or marred by metal-to-metal contact. Nor do your employees want to listen to metal screeching against metal. Use Flex-guard button brushes on your turret head press to replace metal roller balls, prevent scratches and marring, and cush your sheet metal. Brush tables with button brushes can be created and installed on your machines to match your fabricating process’s exact specifications.

Contact Flex-guard for more information on brush tables with button brushes: salesinfo@flex-guard.com

![]() Button Brush Tables – Bed Brushes – PDF

Button Brush Tables – Bed Brushes – PDF

QUIET ENVIRONMENT • NON-ABRASIVE SURFACE • SMOOTH OPERATION

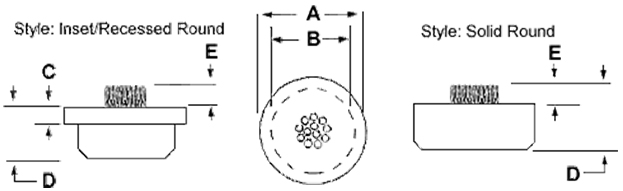

Button Brushes Design Specification

Flex-Guard has a wide variety of different size Button Brushes. Let us help you design the right Button Brush for your application. For more information on Flex-guard Button Brushes Design Specification, please complete the form below and press Send.

All measurements are in inches.